GS 5T Bench-Top Catheter Overmolding

The Pezo GS-5T is a compact, bench-top injection molding press built for teams who need real molded parts without the cost or complexity of full-scale molding equipment. It runs on 120V power and standard shop air, switches materials quickly with zero waste, and is ideal for prototype handles, insert molding, and low-volume builds. Durable, portable, and simple to operate—the GS-5T gives R&D and manufacturing teams a fast, low-risk way to mold production-quality thermoplastics.

GS-5T

The GS-5T is purpose-built for quick iteration and small-batch molding. Its pneumatic ram, simple controls, and small footprint make it easy to place directly on an ELEVT™ workstation or in tight cleanroom spaces. A single operator can switch materials in minutes and run insert molds up to 0.25 oz.

Key Benefits:

- Ideal for R&D, prototyping, and short-run manufacturing

- Quick material changes with no wasted resin

- Simple setup—120V AC and standard 125 psi shop air

- Supports all common thermoplastic materials

- Proven reliability with units running daily for 10+ years

GS-5T Specifications:

- Size: 24" H × 17" W × 25.5" D

- Weight: 230 lbs

- Injection Pressure: Up to 10,000 psi at ram

- Shot Size: Up to 0.25 oz

- Clamp Pressure: 5 US tons (air-over-hydraulic)

- Temperature Control: Barrel, nozzle & clamp up to 700°F / 300°C

- Electrical: 120V AC

- Air: 125 psi, clean and dry

GS-5T Plus

The GS-5T Plus builds on the GS-5T platform with higher injection pressure and an integrated PLC/HMI control system—ideal for teams who want tighter process control and repeatability while staying within a bench-top format.

GS-5T Plus Enhancements:

- Higher injection pressure (14,000 psi at ram)

- Integrated PLC & touchscreen HMI

- Store and recall up to 30 molding recipes

- Same 0.25 oz shot size and 5-ton clamp

GS-5T Plus Specifications:

- Weight: 350 lbs

- Injection Pressure: 14,000 psi at ram

- Shot Size: Up to 0.25 oz

- Clamp Pressure: 5 US tons

- Temperature Control: Up to 700°F / 300°C

- Control System: PLC with HMI

- Recipe Storage: 30 programs

- Electrical: 120V AC

- Air: 125 psi, clean and dry

Frequently asked questions

What kinds of parts can the GS-5T and GS-5T Plus mold?

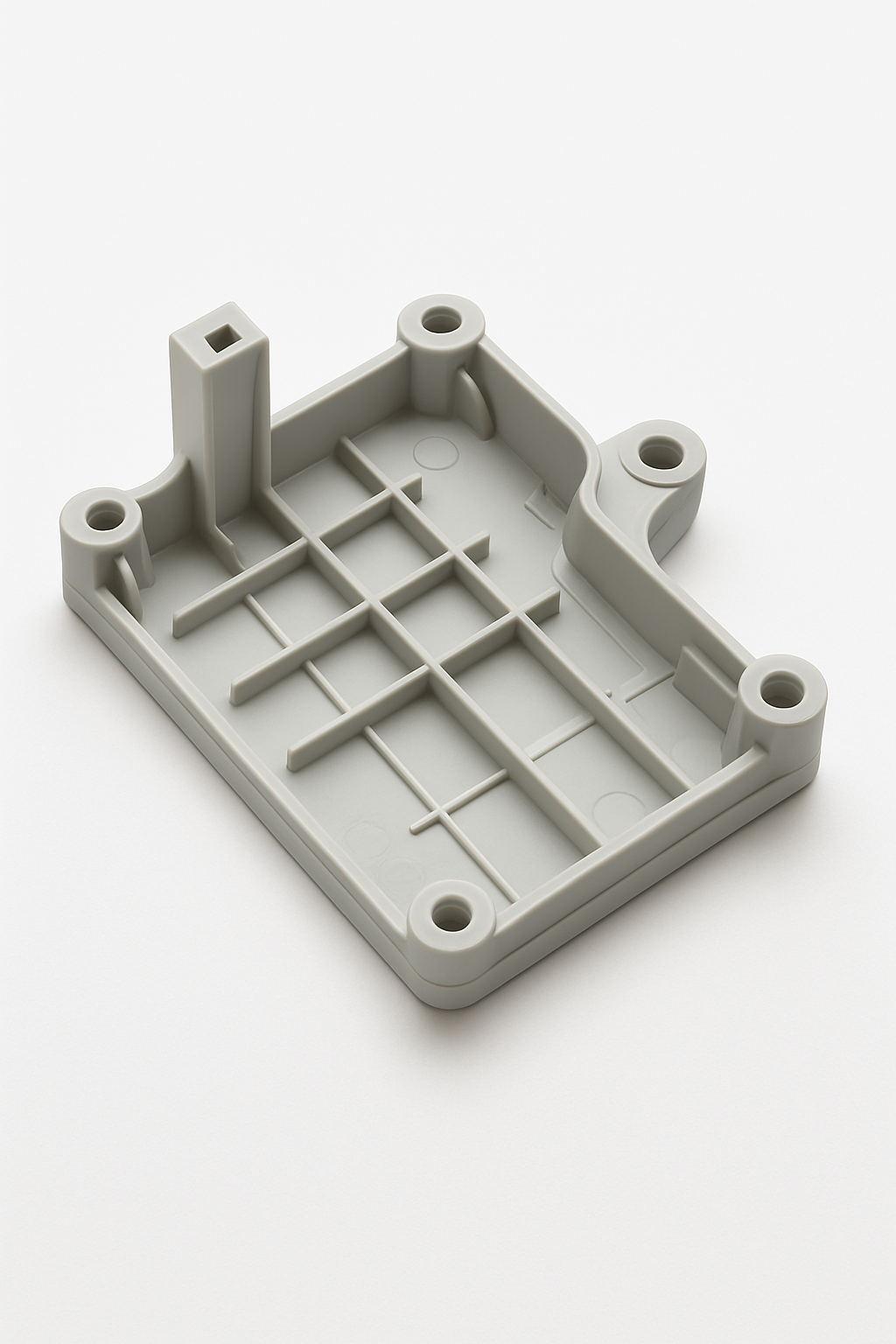

Both machines support all common thermoplastics and are ideal for small, single-cavity parts up to 0.25 oz—such as catheter handles, strain reliefs, insert-molded components, and R&D prototypes.

What’s the difference between the GS-5T and GS-5T Plus?

The GS-5T Plus delivers higher injection pressure, PLC/HMI controls, and recipe storage for more repeatable processing. The GS-5T is simpler and lighter, perfect for quick-change R&D and prototyping.

Do I need special utilities or a dedicated molding cell?

No. Both machines operate on 120V AC and standard 125 psi shop air. They can be placed directly on an ELEVT™ workstation or benchtop in a cleanroom.

Can Pezo build the tooling?

Yes. Pezo designs and machines single-cavity tools, inserts, and fixtures in-house. You get a complete, integrated molding setup tuned to your part and process.

When should I move from a GS-5T to a full-scale molding press?

When volumes grow or you need multi-cavity throughput. The GS-5T platform is perfect for development, low-volume production, and pilot lines—while larger presses (Arburg, Boy, etc.) are better for high-volume programs.