From idea to prototype - faster.

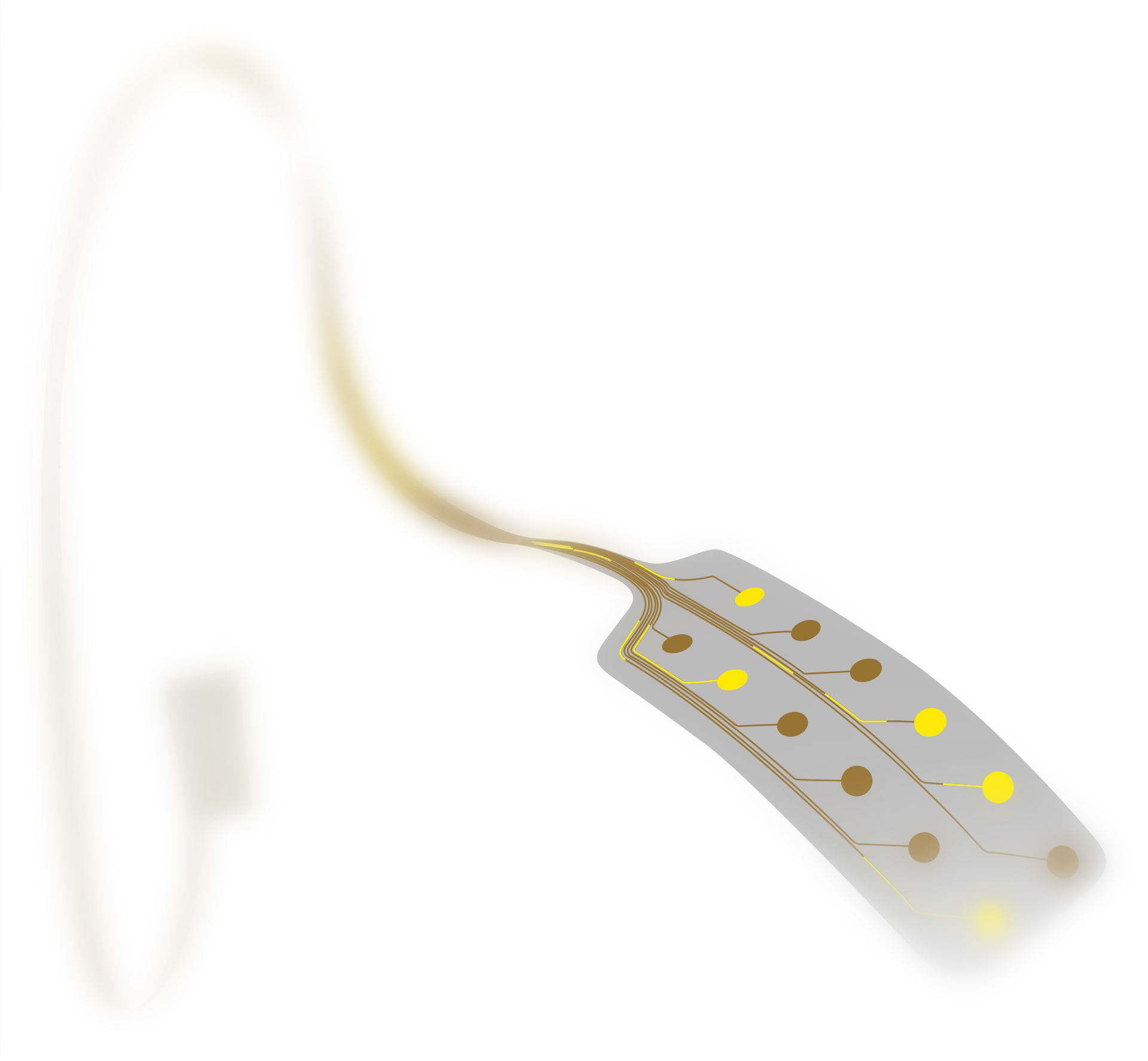

We turn medical concepts into manufacturable designs that investors, engineers, and operators can all believe in, like the NeuroOne thin film electrode.

Make your concept real.

When speed and precision matter, we act as your embedded design team.

Our engineers work side-by-side with you to transform early CAD or napkin sketches into functional, testable prototypes - fast enough to hit your next funding milestone.

We speak both languages: the creative energy of product development and the hard realities of manufacturing. That’s how we keep your design agile, manufacturable, and compliant from the start.

CAD modeling & mechanical design (SolidWorks)

We turn concepts into manufacturable designs without slowing you down. Our team builds clean, reliable SolidWorks models that account for real-world constraints—tolerances, materials, ergonomics, process flow, and downstream manufacturing needs.

Whether you’re proving out an early idea or refining a production-ready assembly, we collaborate in real time, iterate quickly, and design with the operator and the cleanroom in mind. The goal is simple: get you to a working, buildable solution faster.

Rapid prototyping (3D print + GS-5T bench-top molding)

Prototyping here mirrors how you’ll build it on the line. We print, machine, and overmold parts in-house, so you can evaluate true fit, flow, and function early. The GS-5T lets us mold catheter handles and other components exactly as they’ll be produced—ideal for startups and teams racing toward milestone deadlines.

Design for manufacturability (DFM / DFA)

We design parts and assemblies that are easy to build, repeatable, and cost-effective from day one. Our team reviews geometry, tolerances, materials, fixturing, and workflow to remove risk before it shows up on the floor.

By integrating DFM/DFA early, we help you avoid rework, cut scrap, and ensure your product can move smoothly from prototype to production—especially in cleanroom, catheter, and other human-intensive manufacturing environments.

Prototype testing & validation

We make sure your concept actually works in the real world. Our team tests prototypes for fit, function, durability, ergonomics, and process reliability—using the same mindset your production environment will demand.

From simple fixtures to full catheter or cleanroom workflows, we validate what matters early so you can move forward with confidence, reduce surprises, and lock in a design that’s ready for manufacturing.

Embedded R&D engineering teams

When you need more hands and minds, we plug our engineers directly into your team. You get immediate bandwidth from people who can design, prototype, troubleshoot, and build—without the overhead of hiring.

We work inside your process, adapt to your tools, and help you move faster from concept to validation. It’s real-time collaboration with engineers who can solve problems others can’t or won’t.

Frequently asked questions

What stage of development should we be in before working with Pezo?

If you have anything from a napkin sketch to early CAD, you’re in the right place. We help teams turn early concepts into functional prototypes that can be evaluated, tested, and shown to investors or leadership.

How fast can Pezo deliver prototypes?

Speed is a core strength. Because our design engineers sit side-by-side with our machining and prototyping teams, we can iterate in days—not months. Timeline depends on complexity, but we’re built for aggressive milestone-driven schedules.

Can you help us design for manufacturing (DFM), or do you only create prototypes?

We do both. Every prototype we build is also reviewed through the lens of manufacturing reality—cleanroom workflows, tooling, assembly steps, and regulatory considerations. You get a design that works now and scales later.

What makes Pezo different from traditional design firms?

We blend product design with hands-on manufacturing expertise. That means fewer surprises downstream, faster iteration, and prototypes that are grounded in real production constraints. In short: we make concepts real—without the disconnect between design and the manufacturing floor.

What sets your digital marketing agency apart from others in the industry?

Our digital marketing agency offers services such as social media management, search engine optimization (SEO), pay-per-click advertising, content marketing, email marketing, and website design and development.